Capture

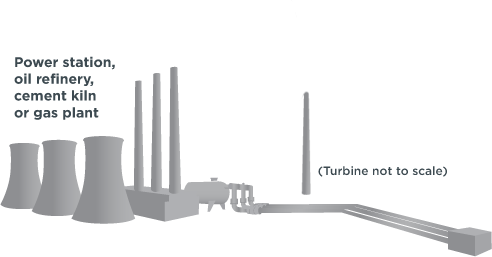

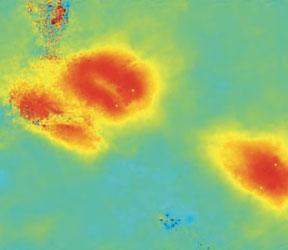

Over 90% of the CO₂ produced by fossil fuels at large fixed installations can be captured and prevented from reaching the atmosphere. Three main technology types - pre-combustion, post-combustion and oxy-firing - are available, allowing CO₂ to be captured from industrial processes such as power generation, oil refining and cement manufacture.

The component parts of the pre-combustion technology exist today at commercial scale; the challenge now is to integrate these in a power application.

Post-combustion can be installed on both new and existing power plants - of vital importance given that the average power plant operates for 40 years. The challenge around post-combustion is to scale-up the technology for use in commercial power applications and integration.